hustle domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /wordpress/wp-includes/functions.php on line 6114

Notice: Function _load_textdomain_just_in_time was called incorrectly. Translation loading for the rocket domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /wordpress/wp-includes/functions.php on line 6114

Notice: Function _load_textdomain_just_in_time was called incorrectly. Translation loading for the wordpress-seo domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /wordpress/wp-includes/functions.php on line 6114

Warning: count(): Parameter must be an array or an object that implements Countable in /www/wp-content/plugins/wpo/inc/propaganda3/wpo/MetaBase.php on line 23

Warning: count(): Parameter must be an array or an object that implements Countable in /www/wp-content/plugins/wpo/inc/propaganda3/wpo/MetaBase.php on line 23

Warning: count(): Parameter must be an array or an object that implements Countable in /www/wp-content/plugins/wpo/inc/propaganda3/wpo/MetaBase.php on line 23

Warning: count(): Parameter must be an array or an object that implements Countable in /www/wp-content/plugins/wpo/inc/propaganda3/wpo/MetaBase.php on line 23

Warning: count(): Parameter must be an array or an object that implements Countable in /www/wp-content/plugins/wpo/inc/propaganda3/wpo/MetaBase.php on line 23

When processors of flour, or flour based mixtures, want to package their product into bags for sale/shipment to potential customers, the go-to machine is usually an auger type filler. Flour by its nature is not a consistently fluidizable material and thus not a good candidate for air packers and not free flowing enough to work on gravity type fillers. Add in the ingredients in a typical bakery mix (sugar, shortening baking soda, and flavorings) and these poor flow characteristics become amplified along with the increased sensitivity to cross contamination. Most auger fillers have a single auger and were designed to handle industrial minerals. They are simple machines that are designed to be robust and work on the same material day in and day out but they are the slowest of all fillers and food grade was usually not part of the original design basis.

In the early 90’s there was a surge in demand of bakery mix production and packaging with the invention of the home bread machine that every housewife got for Christmas. While the standard auger fillers worked with the mixes, they had 3 major drawbacks:

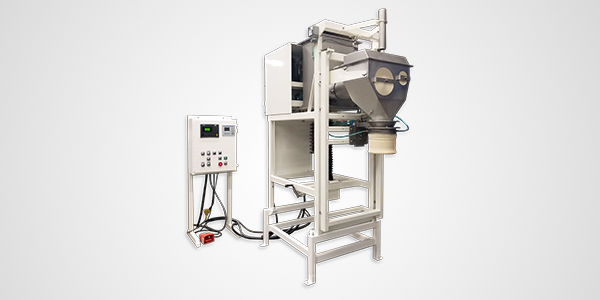

So to answer this demand, Magnum Systems set out to design an auger filler that not only solves these drawbacks, has previsions for filling various container types, prevent dust, and pairs with automated bag placing based on automation/manpower required. The bagging machine created was the APO Dual (Auger Packer Open mouth Dual)

The APO Dual is a “Gross Weigh” filler, meaning that the container being filled is weighed as it is filled. It uses two horizontally mounted augers, one 8” and one 4” to meter and control material flow. These augers each have a positive shut-off cap to ensure halted flow when they stop for increased accuracy assurance. Located above the auger inlet, a ribbon type agitator ensures consistent flow and even feed to the augers. The augers discharge through an enclosed chamber to an inflatable spout where the container (or its liner) is normally attached for filling. The unit is load cell based with a digital scale.

To begin a fill cycle, an operator places a container onto the inflatable spout and signals the process to start by either a hand bump or foot switch. The spout is inflated to form a dust tight seal and both augers begin to fill. At the first pre-act condition, typically around 65% of the target fill, the larger auger stops its fill, while the smaller auger continues to fill. At a second pre-act condition, the smaller auger, which is equipped with a variable speed drive, slows to a dribble speed for the final top off. By using this sequence maximum efficiency in balancing speed and accuracy is achieved. When finished, the scale verifies that the bag is within the processors over/under acceptable limits from the target fill weight. If acceptable, the inflatable head is deflated and the container released. If out of tolerance range, an alarm is signaled and the operator must clear it to proceed, alerting the operator to an upset condition.

Speed of fill: Speed of filling is related to the product bulk density, flowability of the material, size/weight of the container to be filled and operator efficiency. It is also interdependent and inversely related to required accuracy (In other words: faster fill typically equals less accuracy). Assuming a flour-based material between 0.48 to 0.72 g/cc (30 – 45 lbs. /Ft³) and a 25 Kg bag to be filled, the APO Dual can fill bags at a rate of up to 6 bags/minute with proper operator interaction.

Accuracy & repeatability of target fill: As stated, accuracy and speed are interdependent. At the fill rates listed above, typical fill accuracy on the APO Dual would be 0.1 Kg at +/- 2 standard deviations of repeatability. Speeds of the augers and their pre-act condition triggers can be adjusted to increase or decrease either speed or accuracy, but the other measure would typically be inversely affected.

Ease of cleaning: The APO Dual comes standard with a drop bottom clean out provision that allows the entire bottom of the unit to be lowered for cleaning to provide complete operator access to the internal product contact areas of the machine. In addition, options are available for front of machine access to the augers and agitator and motorization of the drop bottom to decrease cleaning turnaround time.

Ease of cleaning: The APO Dual comes standard with a drop bottom clean out provision that allows the entire bottom of the unit to be lowered for cleaning to provide complete operator access to the internal product contact areas of the machine. In addition, options are available for front of machine access to the augers and agitator and motorization of the drop bottom to decrease cleaning turnaround time.

Container versatility: The APO Dual can fill open top containers from 10 to 100 Kg. The base machine is configured for open mouth bags in the range of 10 to 50 Kg to be filled. Optional features allow for box/drum filling of up to 100 Kg by placing an attachment onto the front weighing mast.

Dust generation: The standard APO Dual unit transitions the feed of the twin horizontal augers to the bag fill point in an enclosed transition chamber. This hopper includes a dust take away spout that can be connected to the processor’s dust collection system to capture any displaced air during fill. The bottom of the transition chamber is equipped with an inflatable spout. This spout inflates at the beginning of a fill cycle to form a dust tight seal to the bag or liner being filled so that no dust escapes to the atmosphere during the fill process.

Dust generation: The standard APO Dual unit transitions the feed of the twin horizontal augers to the bag fill point in an enclosed transition chamber. This hopper includes a dust take away spout that can be connected to the processor’s dust collection system to capture any displaced air during fill. The bottom of the transition chamber is equipped with an inflatable spout. This spout inflates at the beginning of a fill cycle to form a dust tight seal to the bag or liner being filled so that no dust escapes to the atmosphere during the fill process.

Automation/manpower required: The APO Dual can be used by operator lacing bags onto the spout, starting the fill cycle, then removing the bags by hand and reforming the bag tops for introduction to a sealer or sewing head. It can also be combined with our Open Mouth Placer (TOMP) to automate these functions. The TOMP includes: a bag magazine for the operator to place bags into; bag hanging arms to open a bag and place it onto the bag spout for filling; a reforming mechanism for taking the top of the filled bag and reforming it for introduction to the bag closing device.

While the APO Dual with its speed and versatility is the most common filler we provide to processors of flour and bakery mix materials, Magnum System’s also provides:

The APO | Single Auger Packer

The APO is similar to the APO dual but with only a single 100 mm auger. This configuration provides most of the same features as above but at a lower rate and capital equipment cost. The trade-off is speed. The APO typically fills at 4 bags/minute versus the APO Dual capable of filling at 6 bags/minute.

The APV | Valve Bag Auger Packer

The APV is an auger filler for valve bags as opposed to open mouth bags. Used by some processors, valve bags provide a more “brick like” package than open mouth bags, as valve bags are not required to leave “freeboard” (empty space) at the bag top for sealing/closing of the bag. This tighter package often increases shipping efficiencies by allowing more bags to be placed on a pallet. While traditional valve bags are not widely used in the food industry because of their inability to positively seal, options today which include tuck sleeves and ultra-sonic sealing provide alternatives for some processors. Note: because of restrictions of valve sizes, the APV is only available in a single auger configuration. It is available with an option for an open-mouth adapter kit, making the unit very popular with co-packers who can purchase a single machine to fill both valve and open-mouth bags.

In Summary

The APO Dual is a versatile packer that combines ease of use, speed, accuracy and repeatability in a standard package that is clean, cleanable and cost efficient to implement. Its speed of use, ease of cleaning, and reduction of dust creation allows operators to be more efficient and productive. The APO Dual’s accuracy and fill versatility allows processors to better meet their customer’s demands and expectations.

Related Post

Customized Nuisance Dust Collection and Control in Pneumatic Conveying Systems

11 Pneumatic System Considerations for the Chemical Industry

Choosing the Right Bulk Bag Filling Equipment in the Chemical Industry

Using Robotics to Overcome Manual Palletizing System Challenges